Download SERVICE MANUAL

Transcript

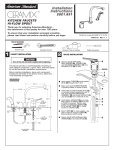

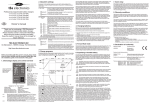

SERVICE MANUAL Models M d l 230 260 280 230 260 280 Dimentions : WxHxD (mm) 540x1169x634 540x1440x634 540x1600x634 DOUBLE DOOR – 230 – 260 – 280 CUSTOMER SUPPORT ASSEMBLE & DISASSEMBLE WHITE GOODS A- Changing The Door Swing Direction to Right Hand 2- Dismantle the refrigerator and freezer door from cabinet by pulling towards to you together with the middle hinge. (Fig-2) 1- Remove the freezer door panel caps. Unscrew the two screws which are fixing the middle hinge. (Fig-1) Freezer door panel right cap Freezer door panel left cap Pull the doors towards to you with middle hinge Unscrew the two middle hinge screws Figure-1 Figure 1 Figure-2 Figure 2 3- Lie down the appliance to the left side. Dismantle both leveling feet and unscrew the bottom hinge fixing screws and remove it. (Fig-3) Unscrew the bottom hinge pin and screw in the next hole.(Fig-4) Then screw the hinge to the left side of the refrigerator. Screw the both leveling feet. Figure-3 Figure-4 1 DECEMBER 2011 DOUBLE DOOR – 230 – 260 – 280 CUSTOMER SUPPORT ASSEMBLE & DISASSEMBLE WHITE GOODS 4- Remove the two big caps on the middle bracket. Unscrew the two screws fixing the top hinge and remove it. Remove the top hinge screw left cap on the left side. Remove the middle hinge screw cap (big) on the right side. (Fig-4) Remove the middle hinge screw cap (big) Remove top hinge screw left cap Unscrew the top hinge Remove the two middle hinge screw caps (big) Figure-4 5- Unscrew the screw fixing the top hinge pin. Turn the pin by 180° then fix it to the top hinge by screwing it. (Fig-5) Rotate the top hinge pin by 180° 180 Figure-5 6- Assemble the top hinge to the left side. (Fig-6) Insert the two middle hinge screw caps (big) to the right side of the middle bracket. (You can find the new caps in the user manual bag) Insert the middle hinge screw cap big to the left side. (You can find the cap in the user manual bag) Insert the top hinge screw right cap to the right side. (You can find the top hinge screw right cap in the user manual bag) Insert the top hinge screw right cap Insert the middle hinge screw cap (big) Insert the two middle hinge screw caps (big) here Figure-6 2 DECEMBER 2011 DOUBLE DOOR – 230 – 260 – 280 CUSTOMER SUPPORT ASSEMBLE & DISASSEMBLE WHITE GOODS 7- Replace the top bushing and top bushing cap. (Fig-7) (You can find the new bushing cap in the user manual bag) Remove the bottom bushing, bottom stopper g, bottom and then assemble the bottom bushing, stopper to the left side. (Fig-7) REFRIGERATOR DOOR BOTTOM STOPPER Figure-7 8- Remove the top bushing and insert it into left hole (Fig hole. (Fig-8) 8) FREEZER DOOR Unscrew the screw fixing the freezer door stopper (right) on the right side and remove it. Than assembly the freezer door stopper (left) on the left side. (Fig-8) (You can find the freezer door stopper (left) in the user manual bag) F DOOR STOPPER F DOOR STOPPER (LEFT) Figure-8 3 DECEMBER 2011 DOUBLE DOOR – 230 – 260 – 280 WHITE GOODS CUSTOMER SUPPORT ASSEMBLE & DISASSEMBLE 9- Turn the middle hinge by 180º . Assemble the freezer door and refrigerator door together with middle hinge. (Reverse operation of item 2) Fix the middle hinge by tighting the screws. (Fig-9) And insert the freezer door panel caps. Turn the middle hinge 180° Figure-9 4 DECEMBER 2011 DOUBLE DOOR – 230 – 260 – 280 WHITE GOODS ASSEMBLE & DISASSEMBLE CUSTOMER SUPPORT B - Changing The Thermostat : 1) Remove the lamp cover and unscrew the fixing screw. 2) Remove the screw cap and unscrew the fixing screw. 3) Remove the thermostat box by pulling it and disconnecting the wire connector. 4) Remove the thermostat knob by pulling forward. Loosen the nut fixing the thermostat. 5) Pull P ll outt the th thermostat th t t bulb b lb from f the th h housing. i 6) Replace the thermostat with a new one and assemble the thermostat box following the steps backwards. C - Thermostat Knob • This Thi knob k b is i used d to t control t l the th temperature t t off the th freezer f and d refrigerator parts automatically. It can be set to any value between “0“ and “5“positions. • “ 0 ” position indicates that the thermostat is “off ”.The refrigerator is “off ” on this setting. • By turning the knob between “1” and “5”, you can increase or decrease the cooling degree. • The refrigerator is designed to get optimum performance when the thermostat knob is set between position “2” to “4”. 5 DECEMBER 2011 DOUBLE DOOR – 230 – 260 – 280 CUSTOMER SUPPORT REFRIGERANT CYCLE DIAGRAM WHITE GOODS F EVAPORATOR CONDENSER DRYER R EVAPORATOR CAPILLARY HOT PIPE SUCTION PIPE 6 SUCTION N PIPE R EVAPOR RATOR F EVAPOR RATOR CAPILLA ARY DRYE ER HOT P PIPE CONDEN NSER COMPRE ESSOR COMPRESSOR DECEMBER 2011 DOUBLE DOOR – 230 – 260 – 280 CUSTOMER SUPPORT TROUBLE-SHOOTING CHART WHITE GOODS No/Insufficient cooling Check the supply voltage (220-240v) Is it ok? Inform customer (220-240v) No Yes Check the voltage at compressor terminals ((220-240v)) Is it ok? No No Is compressor working? Yes Is the power consumption of compressor normal? No Yes Is the thermostat ok? No Yes Replace the thermostat Check thermostat connections No Yes There might be clogging Evacuate the system, (**) Charge the gas again. Yes Break the service pipe, is there any gas evacuation? No Is over load relay ok? Yes Is it working normally ? Yes No Replace over load relay group Compressor windings might be faulty or there might mechanical jamming (***). Check the compressor replace compressor, if needed. Check the compressor, replace if there is problem with pressure. Adjust the thermostat according to seasonal conditions. Check if there is any leakage by the help of foam (*). Fix and Charge the gas again (**). Check the thermostat settings. Adjust the thermostat according to seasonall conditions. (*) Check all pipes, tubes and welding points against gas leakage. (**) Before charging gas to system, change dryer and vacuum at least 30 minutes, then charge the system with amount written on label (***) Compressor primary winding should be around 10 Ω and secondary around 15 Ω (at 250C ambiance temp.) 7 DECEMBER 2011 DOUBLE DOOR – 230 – 260 – 280 CUSTOMER SUPPORT TROUBLE-SHOOTING CHART WHITE GOODS Excessive Cooling Is the thermostat setting appropriate to season conditions? No Adjust the thermostat according to seasonal conditions. Yes Is there any icing formation in refrigerator section? No Is the icing at the whole of back wall (on serpentine)? Yes Yes Set thermostat to a lower setting; did thermostat cut-out? (Compressor stops running) Yes Check the thermostat bulb; does it touch the end of the pipe? If not push the bulb until end No Check the temperature values of fridge section (***) Are they normal? No Is thermostat connections ok? Yes No Compressor pressure might be low or there might me clogging at the system, Check the gas and pressure level, If there is clogging; clean the system (*) and gas charge again.(**) No Yes Correct the thermostat connections Replace thermostat Adjust the thermostat. Inform the customer Replace thermostat 8 DECEMBER 2011 DOUBLE DOOR – 230 – 260 – 280 CUSTOMER SUPPORT TROUBLE-SHOOTING CHART WHITE GOODS Door/Gasket Adjustment Is the ground under the unit is flat? No Product should be on a firm and flat surface Yes Are the adjustable dj bl feet in correct position? No Adjust the feet properly according to ground surface Yes Is there any misalignment at hinge axis or loose screws? Yes Correct the axis and tighten the screws No Is the form of gasket deformed? No As a service solution add 3 washers between the door bottom and hinge. Yes Correct the gasket form with hot water (*). Check after correction. Is the gasket closing properly? No If the gasket is changeable replace the gasket; if not replace the door. Yes Heavy foods/drinks on th d the door shelves h l mustt be shifted to the hinged side. (*) Correct the gasket form by the help of hot water and hair dryer. 9 DECEMBER 2011 DOUBLE DOOR – 230 – 260 – 280 CUSTOMER SUPPORT TROUBLE-SHOOTING CHART WHITE GOODS Abnormal Noise Is the ground under the unit is flat? Adjust the feet properly according to ground d surface No Are the adjustable feet in correct position? iti ? Hayır Product P d t should h ld be b on a firm and flat surface Yes Yes Yes Tighten the compressor feet. Are compressor feet loose? No Are capillary or other loadside pipes touching somewhere? Yes Pipes should not touch any other surfaces. No Is there bitumen on the capillary Yes and on the place that capillary Vacuum the system and make gas charge leaves the heat exchanger ? No Place the bitumen on capillary and on point that capillary leaves the heat exchanger. 10 DECEMBER 2011