Download Miele KF 1903 Vi Specification Sheet

Transcript

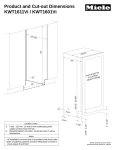

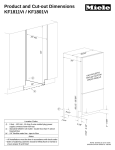

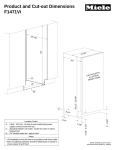

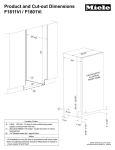

Fully Integrated 36” Bottom Mount KF 1913 Vi / KF 1903 Vi 8mieleusa.com Fully Integrated 36” Bottom Mount KF 1913 Vi / KF 1903 Vi FOR FLUSH INSTALLATION 25" m 84" in.* 4" 35 3/ 24 5/ 8" EPTS ACC TOM T I N U US (2) C S TWO T PANEL N O R F O 36" 83 1/2" - 85 3/8" W E 10 1/ 1 1/8 Location Codes E - 5 foot - 120 Volt - 15 Amp 3-wire molded plug power supply connects lower left rear O - Standard NEMA 5-15 Duplex Outlet - locate less than 9" above finished floor W - 1/4" flexible water line - tape to floor 4 1/8 " 6 5/8" - 8 1/2" " 2" - 8 3/8" 4" Notes • All Installations must be done in accordance with local codes • Sides of adjoining cabinets should be filled (flush to frame) to insure proper fit and finish • For Proud Installation - please adjust accordingly * Depth assumes a 3/4” panel, please adjust according to custom panel thickness KF 1913 Vi / KF 1903 Vi Page 2 of 7 Fully Integrated 36” Bottom Mount KF 1913 Vi / KF 1903 Vi LOWER HINGE LOCATION Hinge FRONT VIEW Upper Door Hinge 1/2" - 2 3/8" 29 11/16" 29 1/8 - 29 1/2" Lower Drawer KF 1913 Vi / KF 1903 Vi Page 3 of 7 Fully Integrated 36” Bottom Mount KF 1913 Vi / KF 1903 Vi CUSTOM PANEL INSTALLATIONS These units do not come equipped with a front panel. They are designed to accept a custom door panel supplied by the cabinet maker. Miele has a unique panel integration system which allows the panels to align with the surrounding cabinets. Panel size is determined in the following manner: Width: Thickness: 35 3/4" in all cases Minumum 3/4" outside frame Panel "B" Height Upper Panel Lower Panel HOM Panel Height Standard Upper Panel Height: 53 5/16" Notes: Finish back side of panels to insure appearance Panel may extend above unit. This is not considered in height calculation Upper Maximum panel weight: 83.8 Pounds Lower Panel Height: Use the following calculation: Panel Height = HOM - 53 9/16 - TKH HOM = Total height of machine. Can be adjusted to match adjoining cabinets - typically 84" HOM is adjustable between 83 1/2" - 85 3/8" TKH = Toe-kick height (2" - 8 3/8") TKH Lower Maximum panel weight: 31 Pounds Upper Panel Notes If the adjoining cabinets are taller than the height of machine (HOM) - the upper panel may be extended accordingly. Find the difference between height of the adjoining cabinets and the height of machine (HOM) and add to 53 5/16" Adjoining cabinet Extended Panel Machine Example: Ajoining cabinet height: Height of machine: Difference: 87" 84" 3" Extended panel height: 56 5/16" KF 1913 Vi / KF 1903 Vi Page 4 of 7 Fully Integrated 36” Bottom Mount KF 1913 Vi / KF 1903 Vi HINGING DETAILS 90° Door 115° Door Thickness options Thickness options 0-1/8" 0-1/8" 0-3/4" 1" 1-1/4" 1-1/2" 1-3/4" 0-3/4" 1" 1-1/4" 1-1/2" 1-3/4" 2" Cabinet Front Cabinet Front 1" Fro nt P ane l 0-3/4" 1-1/2" 1-1/4" 1" 1-1/4" Front Panel 0-3/4" 1-1/2" Door Swing Door Swing 16 7/8" MAX 38 11/16" 7/16" NOTE: Additional space needed depending on thickness of front panels and handle used NOTE: Additional space needed depending on thickness of front panels and handle used KF 1913 Vi / KF 1903 Vi Page 5 of 7 Fully Integrated 36” Bottom Mount KF 1913 Vi / KF 1903 Vi HINGING DETAILS 115° Door Thickness options 0-1/8" 0-3/4" 1" 1-1/4" 1-1/2" 1-3/4" Cabinet Front 13/8”(35mm) 11/6” (29.6mm) 17/24” (18mm) 1/4”(6.4mm) 25/8” (67mm) 21/3” (59mm) 21/24”(52mm) 3/4” 1 (44.5mm) 3”(76.2mm) F r o nt P ane l 0-3/4" 1" 1-1/4" 1-1/2" Door Swing 16 7/8" MAX KF 1913 Vi / KF 1903 Vi Page 6 of 7 Fully Integrated 36” Bottom Mount KF 1913 Vi / KF 1903 Vi HINGING DETAILS FOR INSTALLATION WITH APPLIANCE/OBJECT ON HINGE SIDE 90° Door Thickness options Thickness o 0-1/8" 7/16” 13/16” (11 mm) (30mm) 1-1/4" 1-1/2" 1-3/4" 0-3/4" 1" 1-1/4" 1-1/2" 1-3/4" 2" 17/16” (36.5mm) 111/16” (43mm) 115/16” (49.2mm) Cabinet Front 1" 1-1/4" Front Panel 0-3/4" Handle or object that is NOT flush with Cabinet Front. 1-1/2" Door Swing Door Swi 16 7/8 MAX 38 11/16" 7/16" **When installing hing side next to an appliance or object that is within range of the door panel, limit the door opening angle to 90O. This is done by installing the banking pin as illustrated.Insert the banking pin through the holes and drive in with a hammer. KF 1913 Vi / KF 1903 Vi Page 7 of 7