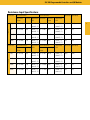

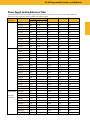

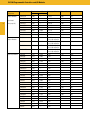

Download AB Quality 1746-P6 Specifications

Transcript