Download User´s Manual - Home - Walter Schulze GmbH

Transcript

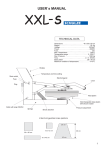

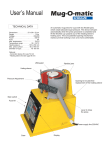

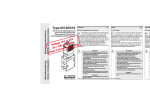

User´s Manual Pneumatic press with two base platens Display Pressure indicator Temperature and time setting Pressure adjustment Pressure switch ON Main switch Circuit breaker 12 A Emergency switch Pressure switch OFF Connection cable from heat platen Clamping bolts for heat platen Grease nipples Base platen Heat platen Base platen Replaceable plates for caps Clamping mechanism for the caps TECHNICAL DATA Dimensions in cm: 170 x 60 x 85 Weight with cabinet stand: 160 kg Voltage: 230VAC Power: 2 KW Air demand per work cycle: 3,3 l Pressure efficiency at 6 bar: 2490 kg Max. pressure: 6 bar Temperature range: 0 - 220 °C Time range: 0 - 9 min. 59 sec. Max. variation of temperature of the heat platen at 180°C (interior temperature of heat platen): -1/+3°C Cabinet stand Clamping bolts 4 pieces M10 Use clamping bolts to bolt the cabinet stand and the press together Replaceable heat platens 10 x 13 cm 20 x 20 cm 38 x 45 cm standard version 40 x 50 cm Replaceable base platens 20 cm 12 x 12 cm 38 cm 20 x 20 cm 10 x 45 cm 38 x 45 cm 40 x 50 cm 43 cm 1 SWITCH ON This device may only be operated by trained staff after reading the USER’s MANUAL. Before you switch on the device, please check if your socket is in proper condition and if the grounding wire is connected properly. The green toggle switch activates the press. The display shows the current temperature of the heat platen and the press will heat immediately until the indicated temperature is reached ( LED 1 is shining). Connect the compressed air hose with the device. The max. pressure in the line may not exceed 6 bar. When not using the device, please pull out the compressed air hose. When using the device over a period of several days without switching it off, then you have to press the black knob left underneath the air connection once a day, to drain the water, which has composed in the filter. PRESSURE ADJUSTMENT The contact pressure is changed through operating the right push-button. Turning the push-button to the right will increase pressure. Turning the push-button to the left will decrease pressure. Impressing the push-button will freeze the current setting. If you want to change the pressure again you will have to pull out the push-button. The pressure can be read off the display which is located in the upper right. 1,0 bar 2,0 bar 3.0 bar 4.0 bar 5.0 bar 6.0 bar - approx. 415 kg approx. 830 kg approx. 1245 kg approx. 1660 kg approx. 2075 kg approx. 2490 kg It is recommended to use the following pressure settings: Caps option: Platens 20 x 20 cm Platens 38 x 45 cm Platens 40 x 50 cm from 0,2 from 0,2 from 0,5 from 0,5 to max. 0,6 bar to max. 1,0 bar to max. 4,0 bar to max. 4,5 bar After each change you should close the press once to check the new pressure setting. Damages due to excess pressure settings are excluded from the guarantee. SAFETY For optimum output and safety it is recommended to read and follow the USER’s MANUAL carefully. Please note that only one person is allowed to work with the press. No second person is allowed to stand next to the press at any time. In case of an emergency push the EMERGENCY SWITCH immediately. By pushing the emergency switch the press will open immediately and block the switch. You cannot move the press downwards again. The emergency switch has to be pulled out to start working again. MAINTENANCE All maintenance works should be done when the device is switched off. You have to pull the plug out of the socket beforehand. When replacing the heat platens you will have to wait until the heat platens have cooled down completely. DANGER OF BURNING !!! There are two grease nipples on the press. They should be lubricated with a grease gun every four weeks. Make sure that the grease infiltrates the bearing when lubricating. The grease has to be temperature-resistant up to 160° C. You can find the grease nipples down at the stack on the left and right as well as above the heat platen. CLEANING The device should be cleaned with a soft cloth. Use domestic dish washing liquid or window cleaning liquid. Scrubbing sponges, solvents or petrol are not recommended. REPLACE SILICONE PAD The device has to be cold. Remove old silicone pad completely from the base platen. Use a pallette knife to equally spread out temperature-resistant silicone. Then apply the new silicone pad. Base plate straight: Put a plate onto the silicone pad and load with weights (approx. 20kg). Let dry for 24 hours. Part for caps: Apply cold heat platen onto the new silicone pad. Fix both plates with paper adhesive tape. Let dry for 24 hours. The silicone pad should be about 1-2 cm bigger than the base platen. Use a cutter to cut edges off after you have sticked both plates together. 2 USER`s MANUAL This press may only be operated by trained staff after reading the user’s manual. PROGRAMMING Temperature Contact pressure 17 x 7 cm 20 x 20 cm 38 x 45 cm 2 max.0,6 bar 3. Use buttons -2 or +3 to set new temperature. Confirmation max.1,0 bar 2,0 bar max.4,0 bar 2,5 bar 40 x 50 cm 1. Hold button 1 for 5 seconds until LED 1 is blinking. 2. LED 1 is blinking and the display shows the preset temperature. The programming mode has been switched on. Time 0,3 bar 0,6 bar 3 max.4,5 bar Programming 1. Confirmation 5 sek. 2. Temperature +/3. Confirmation 1 sek. 4. Time +/5. Confirmation 1 sek. 6. Done 1 4. Press button 1. The display shows the preset time. Change time setting with buttons -2 or+3. 5. Press button 1 to switch off programming mode. LED 1 - The press is heating. LED 2 - Blink diode, programming mode switched on. LED 3 - Temperature range (not active) LED 4 - Temperature setting (not active) The temperatur in °C Example: The time setting is 15 seconds. Minutes Press button 2, the preset time setting is shown on the display. Max. time setting is 9 minutes 59 seconds. TIME TEMPERATURE Press button 3, the preset temperature is shown on the display. Example: Settings for the press This press is used to apply transfers and transfer foils on textiles. Please get in touch with the manufacturer of the textiles, in order to achieve good results. Some settings: Foil Flex Foil Flex S Foil Flock Foil Velcut- 150° - 160° C time 12 sec. 155° - 160° C time 12 sec. 150° - 160° C time 15 sec. 150° - 160° C time 15 sec. All information without engagement. Please arrange own tests before manufacturing. OFF OFF Control PRE-PRESS To open the press before time is up, push the two yellow OFF-buttons at the same time and hold them until the heating platen has reached its top position. Do not swing the press aside until the heat platen has fully stopped. EMERGENCY SWITCH ON ON Pneumatic PRESS In case of a danger situation push the red button in front of the press. The press will open automatically. Pull the red plug out to start working again. Push the green buttons at the same time and hold until the heat platen has moved to its lowest position. The press will open automatically after preset time is over. 3 4 1F25 FILTER 3 1 Stecker/Wtyczka/plug 7 Temperatur(e)sensor 4 230W Heizplatte/plyta grzewcza/heat platen 8 x 16 cm 230W Heizelement/grzalka/heating element 6 S1 time start. . . . . . . . . . . (czarny / schwarz / black ) S4 setup . . . . . . . . . . . . . . . . . . . (zolty / gelb / yellow ) S5 [ - ] Temperatur(e) . . . . . . . . . (zielony / grün / green) S6 [ +] Zeit / time . . . . . . . . . . . . (Brazowy / braun / brown) Temperatur(e)sensor ( - ). . . . . . . .(niebieski / blau / blue) Temteratur(e)sensor (+). . . . . . . . . (czerwony / rot / red) F1 bezpiecznik / Sicherung / fuse 10A F2 bezpiecznik / Sicherung / fuse 12VDC 1,5A 12V+ czerwony / rot / red 12V- niebieski/ blau / blue 3 + 6 grzalka / Heizelement / heating element 1 + 4 czujnik / Temperatur(e)sensor 7 uziemienie / Schutzleitung / grounding wire S10 Hauptschalter/ Wlacznik glówny / main switch N 0 F1 Power supply unit czerwony/ rot/red + Temperatur(e)sensor czarny schwarz 230VAC black 4 5 6 Stecker/Wtyczka/plug F2 1,5A 7 1 2 3 - 12VDC + 3 12VDC 230VAC 6 CRYDOM 50A + CRYDOM K F S S1 ROM-3 A3K1 Z 540 Temperatursicherung/ thermal fuse 1 4 0 - 220°C 7 S2 Zusatzschalter/ additional switch Temperatur(e)sensor KTY 84-1 Stecker/wtyczka/plug Relais 50A Przekaznik elektroniczny relay + -+ - 12VDC Thermoregulator-timer niebieski/ blau/blue Heizelement/grzalka/heating element Temperatur(e)sensor Heizplatte/plyta grzewcza/heat platen 2000W czarny schwarz 230VAC black Netzteil/zasilacz 12VDC SCHALTPLAN POLACZEÑ SCHEMATIC (Electrical Diagram) blau L S10 Setup 230VAC Zeit aus 12V+ Time off S1 S6 S5 S4 Rot/czerwony/red 10 Blau/niebiesk/blue 13 Blau/niebieski/blue Mikroschalter/micro switch Aktiviert die Schaltung nur in Position über der Arbeitsplatte. Only activates the circuit above the base platen. 7 6 Rot/czerwony/red + 12V - 12V 230VAC 11 Ein/ON Ein/ON Rot/czerwony/red Druckschalter EIN Pressure switch ON Elektromagnet/ electro magnet + 12 + - Rot/czerwony/red 8 9 Bewegung der Heizplatte Movement of heat platen 2 Rot/czerwony/red Druckschalter EIN Pressure switch ON Rot/czerwony/red Rot/czerwony/red 14 Rot/czerwony/red S1 5 Mikroschalter Micro switches Weiß/bialy/white 3 Rot/czerwony/red Zeit aus 12V+ Time off +-+12V 44 Weiß/bialy/white 33 Weiß/bialy/white S2 Weiß/bialy/white S2 Druckschalter AUS/ Pressure switch OFF K S S1 F CRYDOM Weiß/bialy/white Druckschalter AUS/ Pressure switch OFF ROM-3 0 - 220°C 0 10 Rot/czerwony/red 1 4 Setup Netzgerät/Zasilacz/power supply Zweihandrelais Wlacznik Obureczny two-hand relay Control of pneumatic for Airpress Blau/niebieski/blue Pneumatikventil/pneumativ valve Druckmesser/ pressure gauge Druckzylinder/ printing cylinder Heizplatte/heat platen + Druckluft max.6 bar/ compressed air max. 6 bar 5 E TESTING REPORT vis-CAP vis-PRESS4050 o Base (varnish, greasing of shafts) o Heat and base platens, symmetry, silicone, teflon o Hours of work at 220°C . . . . . . . o Electrical connection, grounding wire, power cable o Test with transfer foil o Electronics, max temperature 220° C, inspection of all functions o o Hours of work at 180 °C . . . . . . . o Temperature tolerance at 180°C . . . . - / . . . . . +°C Warning stickers o Packaging Serial number . . . . . . . . . . . . . . . . . . . . EC declaration of conformity According to the EC directive 89/37 EC The Walter Schulze GmbH Schmalenbachstr.15 12057 Berlin hereby declares as European agent for the manufacturer Romanik that the following described machine: heat press. . . . . . . . . . . . . . . serial number . . . . . . . . . . . . accords to the terms of the following EC directives: Machine directive ( 89/37) Low voltage directive (72/23) EMV-directive (89/336) Used standards and technical specifications: EN 292-1, EN 292-2 “safety of machines” EN 60204-1 “electrical equipment of machines” Berlin . . . . . . . . . . __________________________ Peter Meidinger CEO 6