Download USER MANUAL - PLAY iT! Amusements

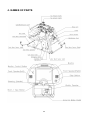

Transcript